Gasoline chain saws, referred to as

chainsaws, are generally used for forest logging, timber building, branching, etc., as well as timber yard building, railway sleeper sawing and other operations. The sawing mechanism is a saw chain, and the power part is a gasoline engine, which is convenient to carry and easy to operate, but is complicated to maintain and repair. If the chain saw appears to turn off the fuel, work less vigorously, or overheat the heater, it means that the chain saw is broken. Hangzhou Longer Sawchain Co.,LTD. From the following aspects, we will introduce in detail how to repair the chain saw when it fails. Let's find out together!

1. Before the chain saw works, let it run at low speed for a few minutes, and see the oil line of the chain saw lubricating the saw chain before starting to work. When working, the throttle can be set to use at high speed. If you haven't finished 1 tank of fuel, you need to rest for a period of time, roughly 10 minutes. After the work is completed, the heat sink of the chain saw needs to be cleaned to ensure the normal heat dissipation of the machine.

2. The air filter of the chain saw needs to be dedusted once every 25 hours. If it encounters special circumstances, it can be adjusted by itself. The cleaning of the foam filter element can be cleaned with washing liquid or gasoline, then washed with clean water, squeezed to dry, then soaked in oil, squeezed out the excess oil to install.

3. When using a new chain saw, you should pay attention to the tightness of the saw chain, so as to push the saw chain to rotate, use a portable saw chain, and the guide teeth are parallel to the guide plate. After a few minutes of use, pay attention to observe again, and repeat this several times. .

When using a chainsaw, make sure that there are no creatures within 20 meters of the surrounding area, and check whether there are hard objects, stones, etc. on the grass to ensure safety. When the chain saw needs to be put aside, it is necessary to clean the body, let off the mixed fuel, and burn out the fuel in the carburetor; remove the spark plug, add 1-2ml of two-stroke oil into the cylinder, pull the starter 2-3 times, install Put on the spark plug.

4. If the chain saw appears to be refueling and flame out, working less energetically, or overheating the heater, it is generally the problem of the filter. Therefore, before working, it is necessary to check the filter. A clean and qualified filter is aimed at sunlight and should be clear and bright, otherwise it is unqualified. If the filter of the chain saw is not clean enough, it should be washed with hot soapy water and dried. A clean filter can ensure the normal use of the chainsaw.

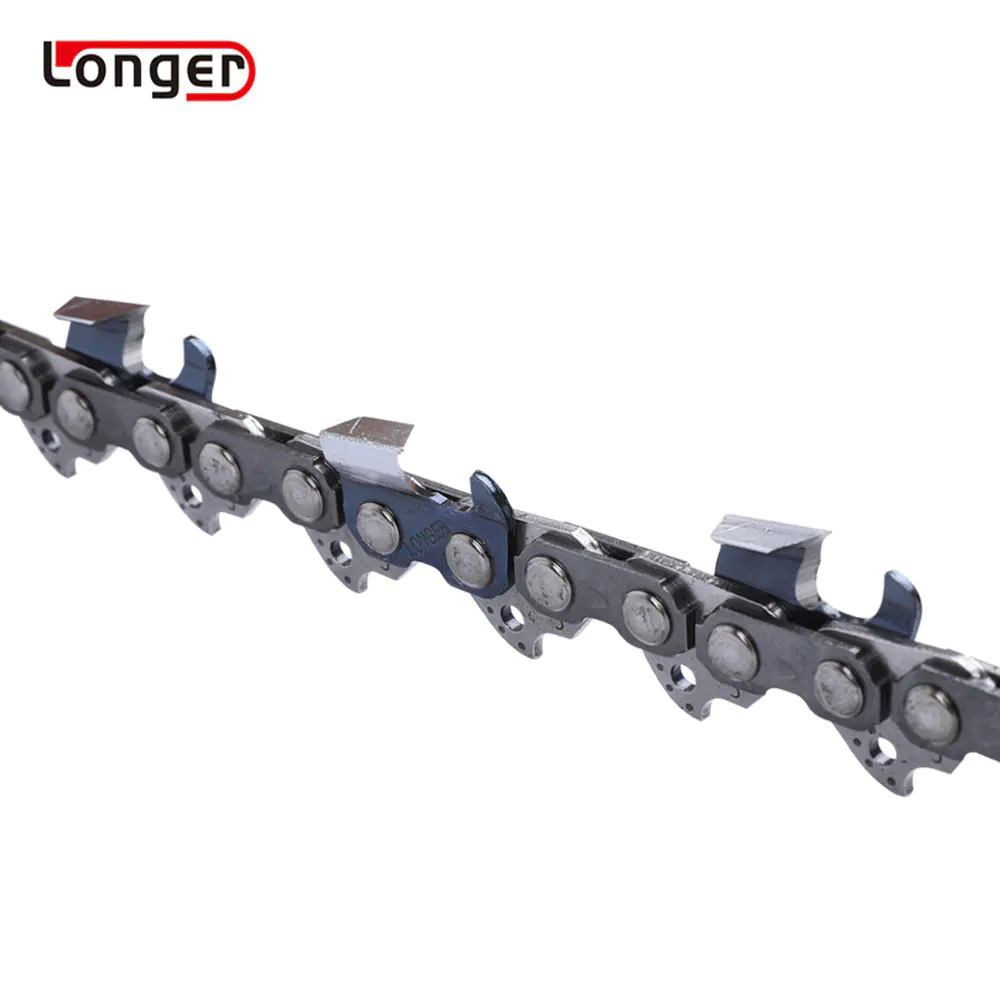

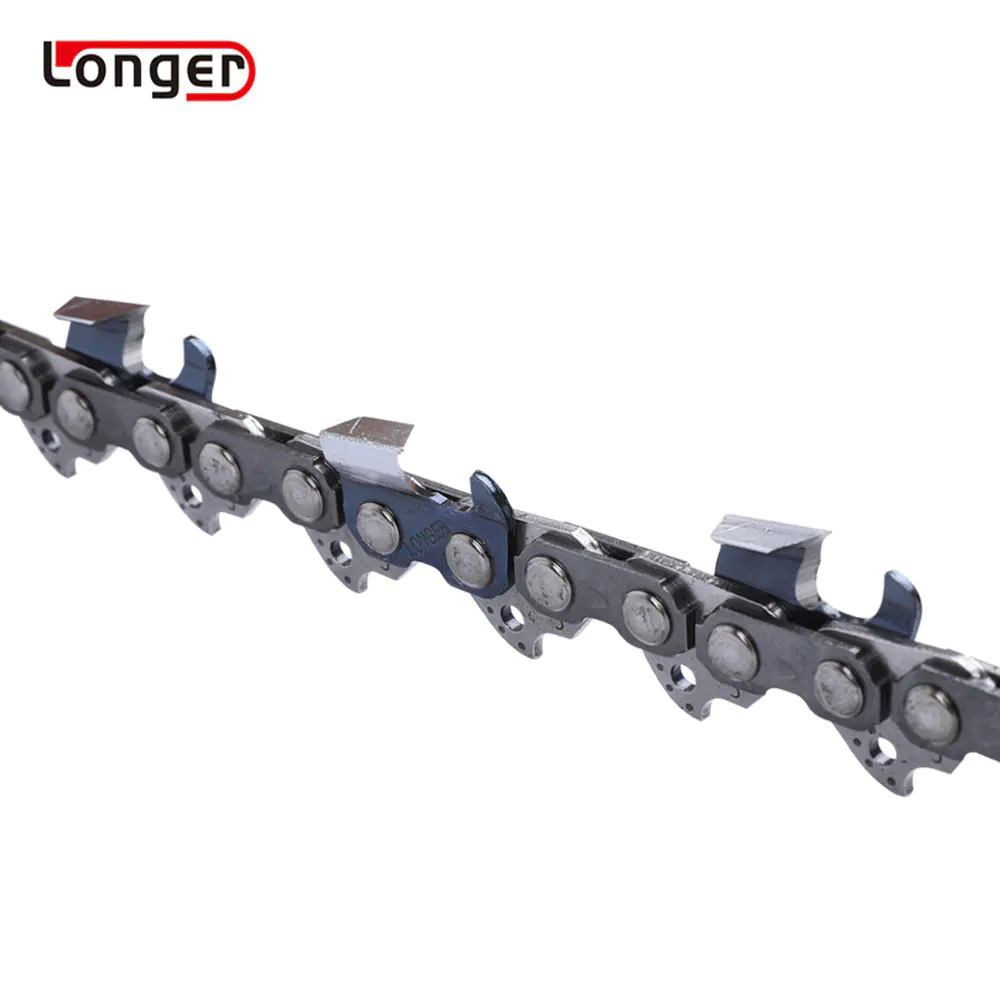

5. When the saw teeth of the chain saw become unsharp, you can use a special file to rest the teeth of the sawtooth chain to ensure the sharpness of the saw teeth. At this time, it should be noted that when using the file to file, it should be filed in the direction of the cutting teeth, not in the opposite direction. At the same time, the angle between the file and the chain saw chain should not be too large, and it is appropriate to be 30°.

6. Before using the chain saw, the chain saw chain oil should be added. The advantage of this is that it can provide lubrication for the chain saw, reduce the frictional heat between the chain saw chain and the chain saw guide plate, and protect the guide plate. It also protects chainsaw chains from premature scrapping.

7. After the use of the chain saw, the chain saw should also be maintained, so that the work efficiency can be guaranteed when the chain saw is used next time. The first is to remove the impurities in the oil inlet hole at the root of the chain saw guide plate and the guide plate groove to ensure the smoothness of the oil inlet hole. Secondly, the debris in the guide plate head should also be cleared, and a few drops of oil should be added.