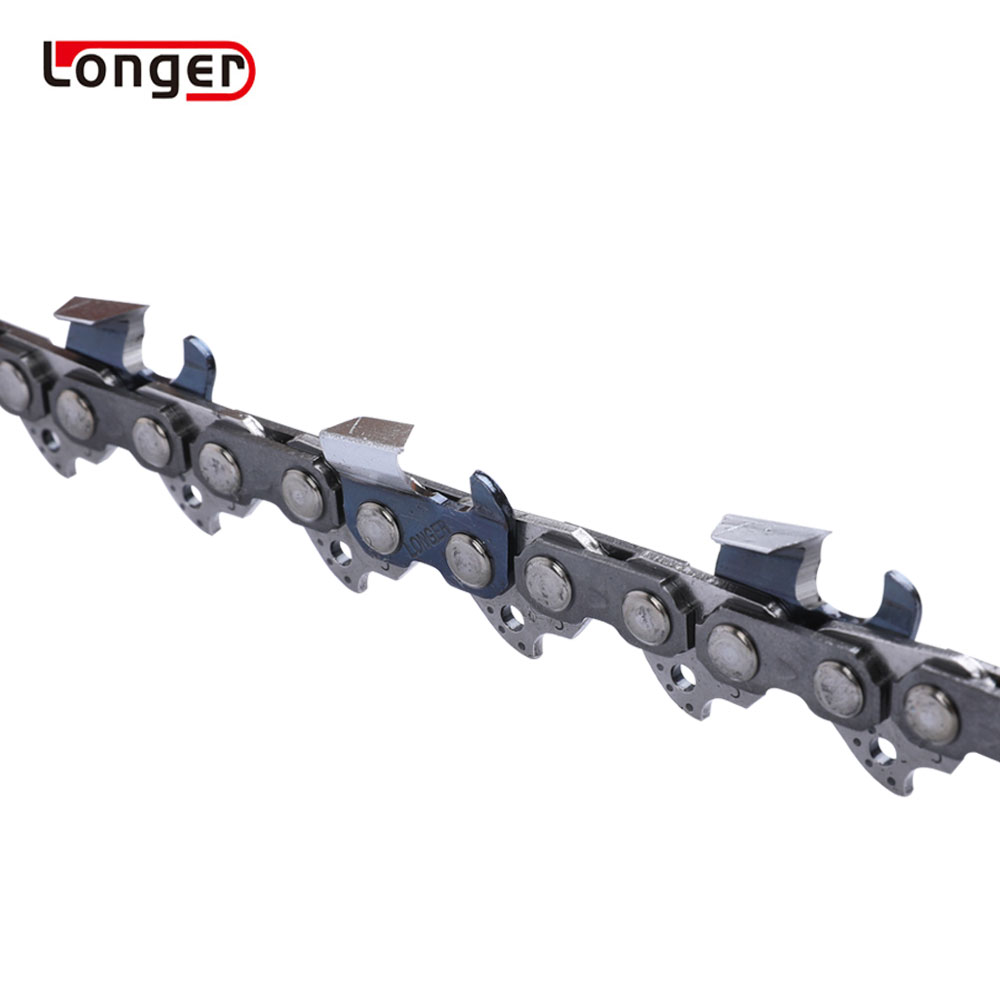

The chain saw guide plate and chain saw chain can be vividly compared to the train and the guide rail. The train jolts and reaches the destination accurately, relying on the support and guidance of the guide rail; similarly, the chain jolts and moves along a straight line at a high speed and also depends on the support and guidance of the guide plate. . So, how are the supporting and guiding functions of the guide plate realized? First of all, we know that the shape of the guide plate is thin and long, and its two fronts have guide rails running through the head and end, and the width of the guide rail is required to complete the support and positioning of the chain; in addition, the straightness of the guide rail also has strict standards , So that the chain can stop linear movement along the guide rail.

The saw chain and the guide plate "cooperate" with each other to complete the sawing operations of the chain saw. Next, we understand the corresponding size parameters of the two. Below are the parameters corresponding to the guide plate and the saw chain, stop explaining one by one: 1. The width of the guide rail (corresponding to the thickness of the middle guide tooth of the saw chain) (unit: inch; 1 inch = 2.54 cm): divided into 0.043, 0.050 , 0.058, 0.063, etc. 2. The pitch of the guide wheel teeth (corresponding to the pitch of the saw chain) (unit: inch): divided into 1/4, 0.325, 1/4, 3/8, 0.404, etc.